Rapid and reliable age estimation is crucial for effectively and efficiently managing fish stocks. Scientists successfully used a novel technology, Fourier transform near infrared spectroscopy (FT-NIR)and artificial intelligence (AI), in combination, to more quickly produce reliable estimates of fish age.

Rapid and reliable age estimation is crucial for effectively and efficiently managing fish stocks. Scientists successfully used a novel technology, Fourier transform near infrared spectroscopy (FT-NIR)and artificial intelligence (AI), in combination, to more quickly produce reliable estimates of fish age.

Otoliths are small calcified structures in the inner ear of a fish, also known as ear stones. Otoliths help fish with hearing and balance. Their value to scientists, however, lies within their layers, which are visible like tree rings. An otolith grows incrementally over the lifetime of a fish, recording a timeline of information about the fish’s biology and environment.

For the past several years, Alaska Fisheries Science Center scientists have been using FT-NIR spectroscopy to determine fish ages. The process involves focusing light from a special near-infrared source on the otolith. The otolith absorbs some of this light at characteristic wavelengths (or frequencies) from 800 to 2,500 cm-1 that is associated with its molecular composition. Scientists measure the amount of light that is absorbed with an instrument known as a spectrometer. The record of the light absorbance by the otolith is called a near-infrared spectrum.

More recently scientists are beginning to use AI models to speed the processing of diverse data sets. To train and test the models, scientists scanned a total of 8,617 walleye pollock otoliths collected during 2014–2018.

“With the help of AI, we are able to produce fish ages faster than traditional ageing methods, ” said Irina Benson, fish research biologist and lead author of a new study published today in Canadian Journal of Fisheries and Aquatic Sciences. “We are also using biological and environmental data to improve our predictions of fish age using otoliths and new technology. ”

Revolutionizing Fish Age Estimation Methods

Each year research scientists examine up to 40,000 fish otoliths of more than 15 species to determine their age. Almost 15,000 walleye pollock otoliths are aged annually for the stock assessment model. This model provides estimates of pollock abundance, which resource managers then use to determine annual catch limits in commercial fisheries.

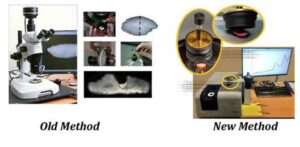

At sea on vessel surveys or during dockside sampling, scientists collect otoliths from fish. To see the growth rings, traditionally scientists have to prepare the otolith. This requires them to burn or take a slice, or cross section, out of the otolith with a special saw. Scientists can then count the growth rings under a microscope. An independent analyst produces a second age estimate to validate the initial findings and estimate age reading precision.

Using FT-NIR and AI analysis, the process of ageing a fish is much more efficient. It takes just 30–50 seconds per otolith to estimate the age of the fish. This is more than 10 times faster than traditional methods.

The AI model also provides more accurate ages for older fish because these kinds of models are capable of accepting and learning information from many more sources of data.

Enhancing Fish Stock Assessments

Around the world, fisheries stock assessments rely on several types of important data derived by studying fish otoliths. With this information, scientists are able to determine whether overfishing is occurring or if a fish stock is overfished. This information includes:

- Estimated ages of the various fish in a given fish stock

- Estimated average size at age of fish in a stock

- Estimated age at which fish in a stock reach maturity

- Estimated lifespan of fish in a fish stock

“This novel approach has the potential to vastly increase the efficiency and repeatability of production age estimation for stock assessments. It has the potential to enhance the quality of fisheries stock assessments across NOAA Fisheries and potentially worldwide,” said Tom Helser, co-author and Alaska Fisheries Science Center Age and Growth Lab Program Lead. “The next step is to use these new age data products in stock assessment models. If all goes well, we hope to begin to integrate the new age estimation process into our daily operations.”

[content id=”79272″]